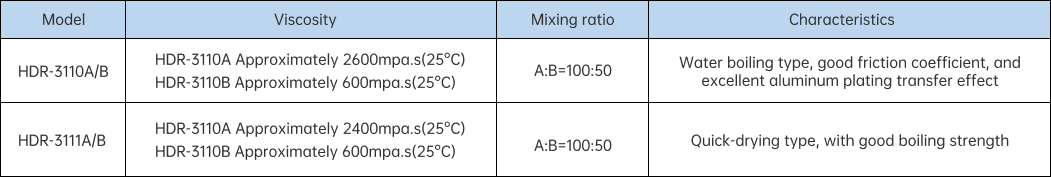

Solvent-free Polyurethane Lamination Adhesive

Solvent-free lamination adhesive is a solventless, two-component polyurethane adhesive, mainly used in the flexible packaging industry. Simple operability, high cost-performance, good strength, and good medium resistance make it an excellent option for flexible packaging lamination.

1

Hook-and-loop fastener composite

| Solvent-free Polyurethane Lamination Adhesive |

Online customer service

Online customer service Product Center

Product Center Contact us

Contact us Return to the top

Return to the top